The American Battery Technology Company (ABTC) has recently made headlines with the awarding of a substantial $144 million grant from the U.S. Department of Energy (DOE) to construct a state-of-the-art lithium-ion battery recycling facility in Reno, Nevada. This facility represents a crucial step forward in the burgeoning field of sustainable battery recycling, enabling the processing of end-of-life batteries and the recovery of vital materials needed for the growing electric vehicle (EV) market. In this article, we will delve into the innovative aspects of ABTC’s new facility, highlight its expected impact on the local economy, and discuss the significance of job creation in fostering community support for sustainable initiatives. This move not only marks a pivotal moment for ABTC but also positions it as a leader in the transition towards a circular economy for battery metals.

Key Takeaways

- American Battery Technology Company receives a $144 million grant to build a lithium-ion battery recycling facility in Nevada.

- The new facility will significantly enhance processing capacity and produce battery-grade materials for the North American market.

- The project is set to create 1,500 jobs in construction and operations, supporting local economic growth and sustainable initiatives.

Overview of the Lithium-Ion Battery Recycling Facility

## Overview of the Lithium-Ion Battery Recycling Facility

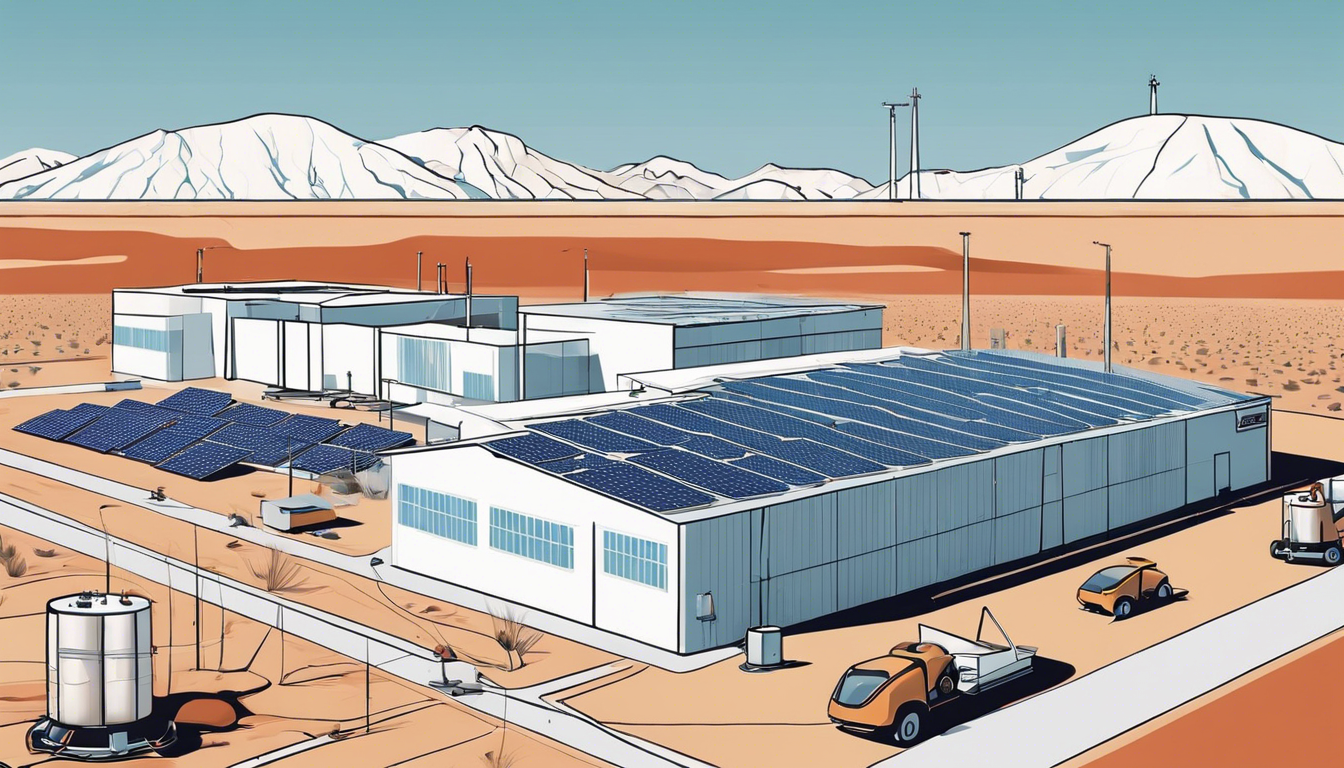

American Battery Technology Company (ABTC), a pioneering enterprise based in Reno, Nevada, is making headlines with its recent award from the U.S. Department of Energy (DOE)—a substantial grant totaling $144 million. This funding is designated for the construction of a cutting-edge lithium-ion battery recycling facility, marking ABTC’s second commercial facility of its kind. With the capacity to process approximately 100,000 tonnes of battery materials annually, this new facility will primarily focus on recycling end-of-life batteries and scrap materials, subsequently producing battery-grade nickel, cobalt, manganese, and lithium hydroxide for the North American market.

The strategic partnership between ABTC and BASF, a prominent cathode manufacturer, further amplifies the significance of this initiative, as BASF intends to purchase the metals generated through ABTC’s innovative recycling process. CEO Ryan Melsert expressed pride in successfully securing this competitive grant, noting its crucial role in enhancing the company’s capacity to cater to the increasing demands from the U.S. automotive and battery sectors. The facility is designed to significantly boost processing capabilities—by a factor of five—compared to ABTC’s existing operations. Importantly, it will employ advanced and sustainable recycling techniques, moving away from conventional methods that often rely on high-temperature smelting, which can be resource-intensive and less environmentally friendly.

Moreover, the new facility is set to generate considerable employment opportunities within the community, creating around 1,200 construction jobs and 300 operational positions. This not only supports local economies but also aligns with broader sustainable initiatives that resonate with increasing public consciousness about green technologies. Scheduled to begin operations on January 1, 2025, this grant submission reinforces ABTC’s unwavering commitment to innovation, positioning the company at the forefront of the electric vehicle and battery market while promoting a circular supply chain for battery metals. As the world continues to prioritize sustainable practices, such advancements in recycling technologies underscore the potential for significant environmental impact and economic growth.

Impact on the Local Economy and Job Creation

The establishment of the new lithium-ion battery recycling facility by American Battery Technology Company (ABTC) in Reno is poised to make a transformative impact on the local economy. With the projection of generating 1,200 construction jobs and 300 operational roles, this initiative will not only bolster employment rates but also stimulate local businesses as workers contribute to the economy through their increased spending. The facility’s focus on sustainability aligns perfectly with community values, fostering a sense of pride and engagement among residents. Additionally, the strategic partnership with BASF ensures a stable demand for the recycled materials, which can further enhance economic stability. By creating a robust supply chain for essential battery metals, ABTC is positioning itself as a key player in the booming electric vehicle sector, thereby attracting additional investments and innovations that can further energize the region’s economic landscape.

About Obtainium Science and Surplus

Obtainium Science and Surplus has been a trusted source of surplus scientific and industrial equipment since 1999. Focusing on reliability and competitive pricing, Obtainium helps professionals and enthusiasts find unique and essential components. Visit Obtainium Science and Surplus to discover more.